Get better visibility on your delivery teams

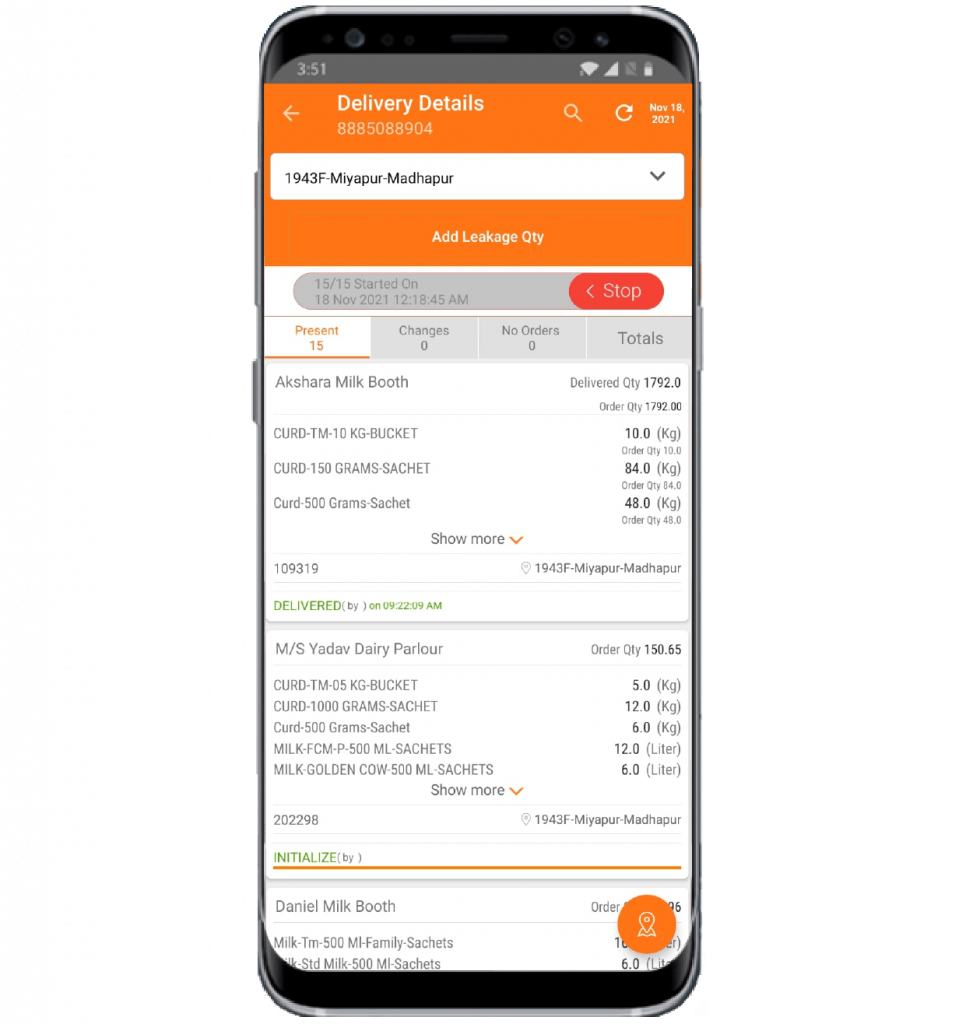

Through the vehicle tracking module, logistic managers have better visibility and control of their delivery vans. Based on the number of orders and delivery location for each of them, an optimized route is generated, which allows delivery teams to fulfil every order in the shortest time possible. With GPS integration and navigation enabling, knowing the exact location of a van becomes easier in real-time. Any diversions, stoppages, or detours are instantly reflected on the system and the control centre executives can take necessary actions to ensure smooth and on-time delivery.