Achieve Efficient Milk Transportation

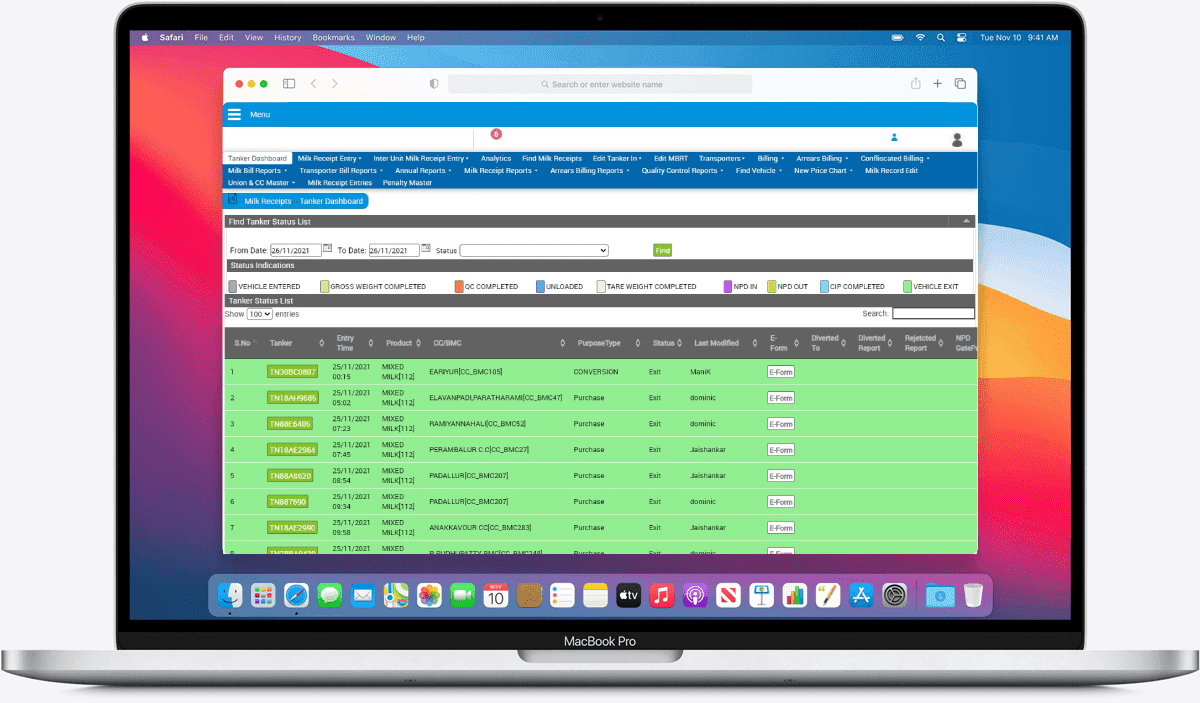

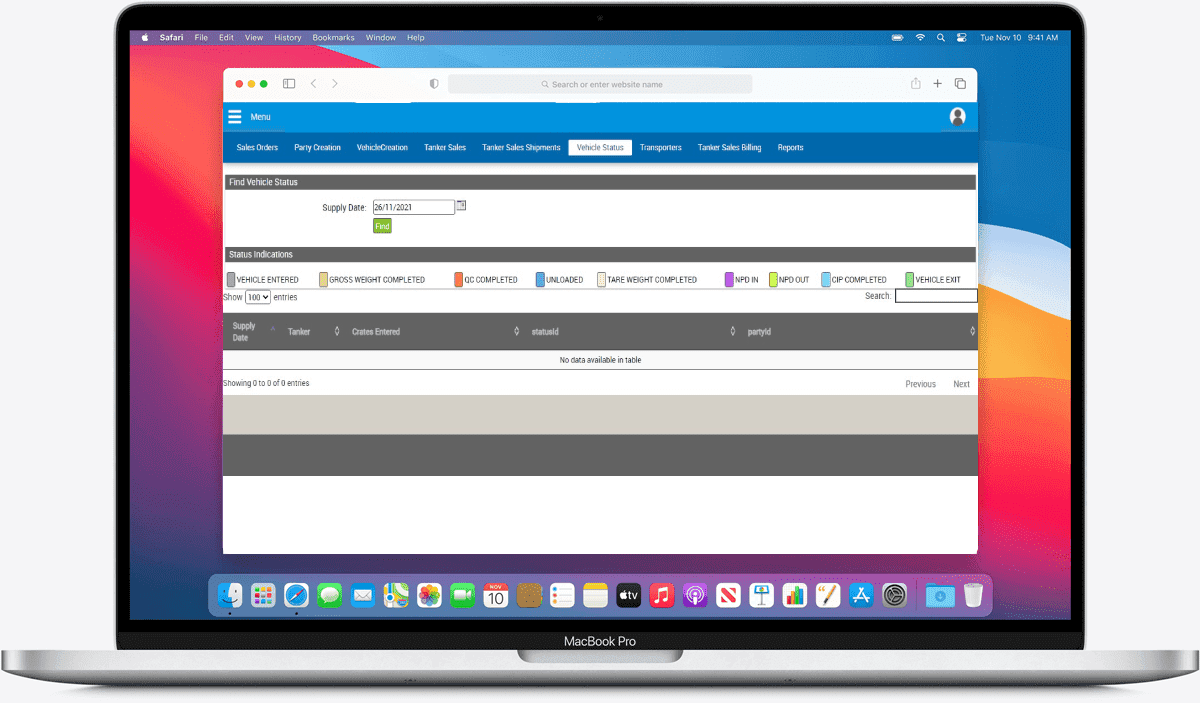

Milk movement from BMCUs to the downstream is an important activity in Dairy management. Milk is a perishable item and starts getting spoiled quickly. Market demand vs. milk collected from farmers will never match. Selling milk as milk to other market players or forward contracts to purchase in case of deficiency is a continuous activity. Balancing fluctuations during the lean and flush seasons etc. needs continuous monitoring and coordination. Moving milk entails complex logistics interventions and Incident handling. Real-time visibility and historical trends help planning these activities better.

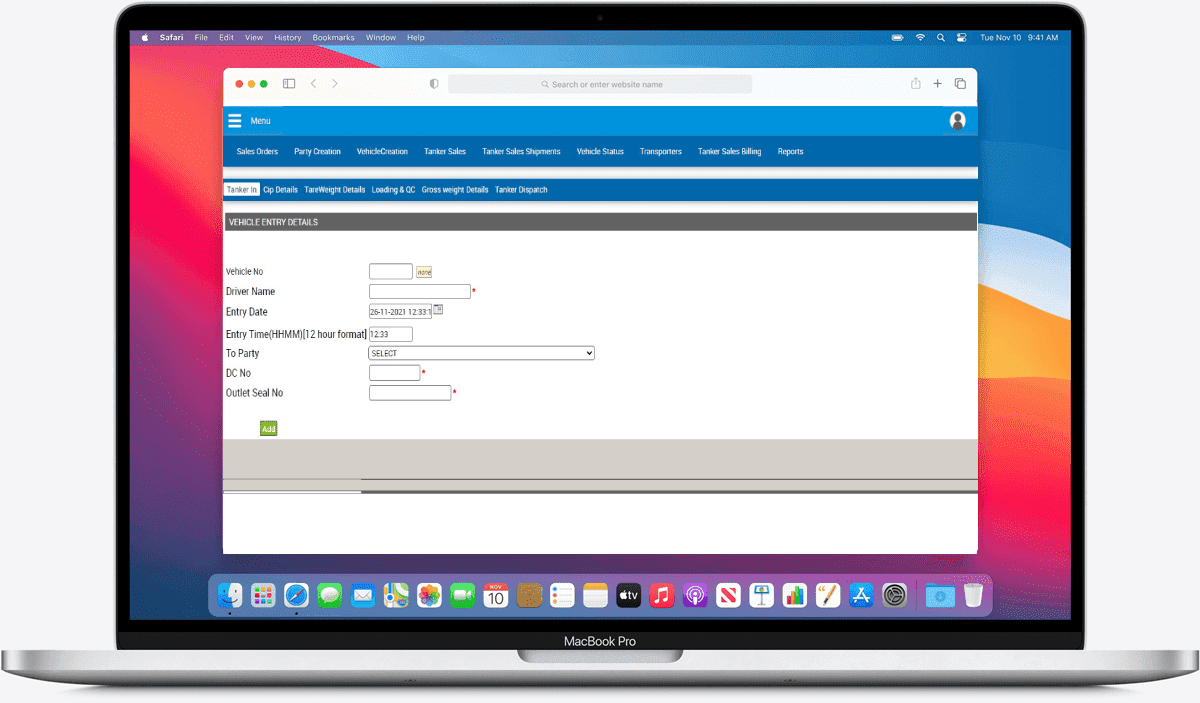

Milk tankers are not ordinary trucks. They carry specially designed insulated tanks that keep the temperature inside the tanker suitable for milk. A tanker can contain anywhere from 5000 to 15000 liters of milk and deploying a tanker with needed capacity saves costs. Contract management with transporters entail stringent checks to verify the condition of the vehicle with proper insulation infrastructure, other accessories like stepney tyres etc. go a long way in risk mitigation in the milk transportation. Milkosoft in-built controls ensure that only registered tankers with fitness check periodically as well as carry insurance cover only are deployed for operations.