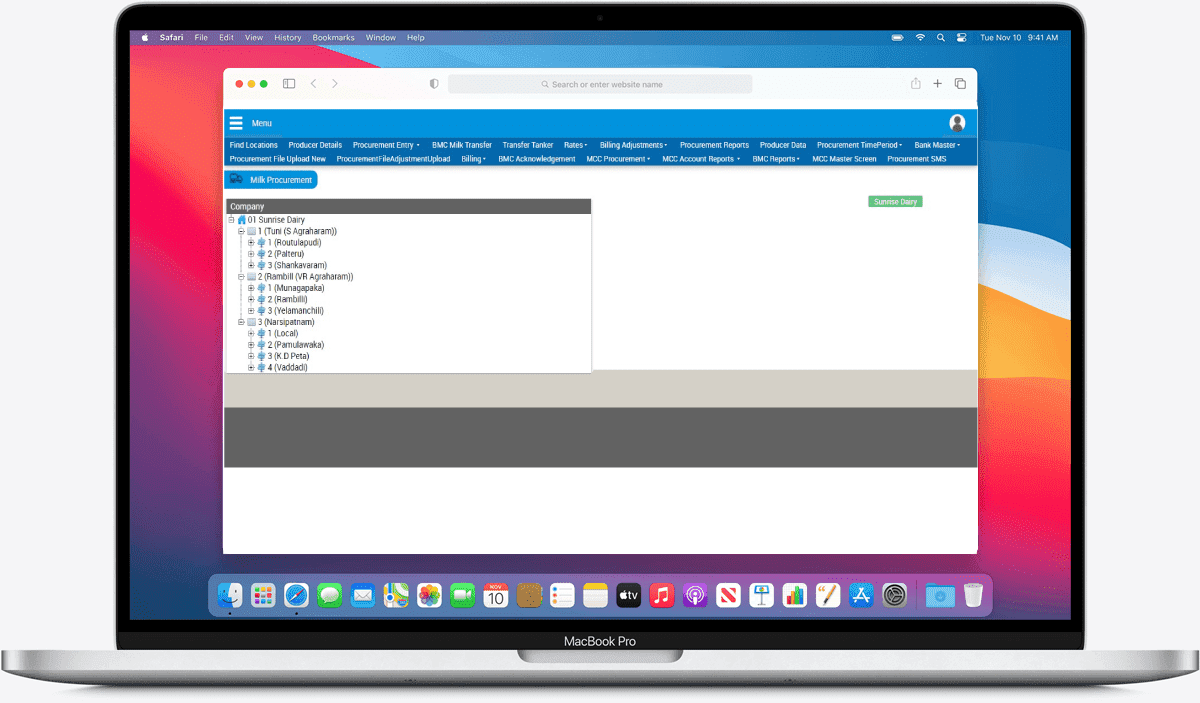

Manage BMCU Milk Collection Data

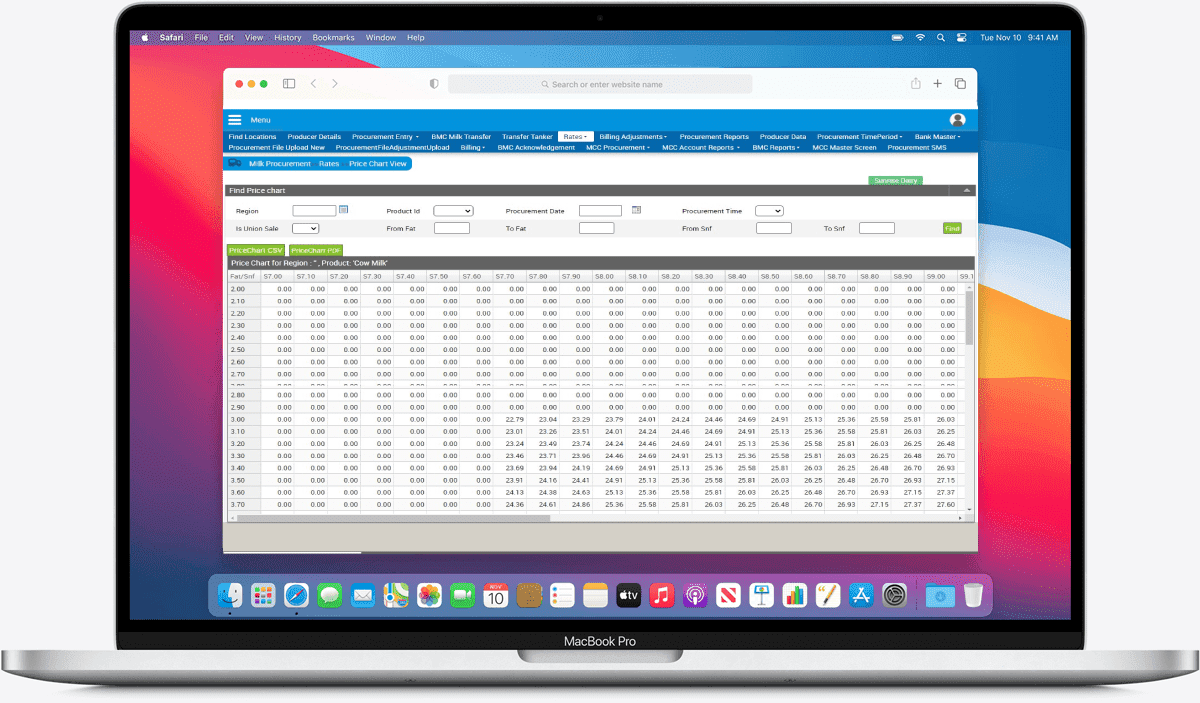

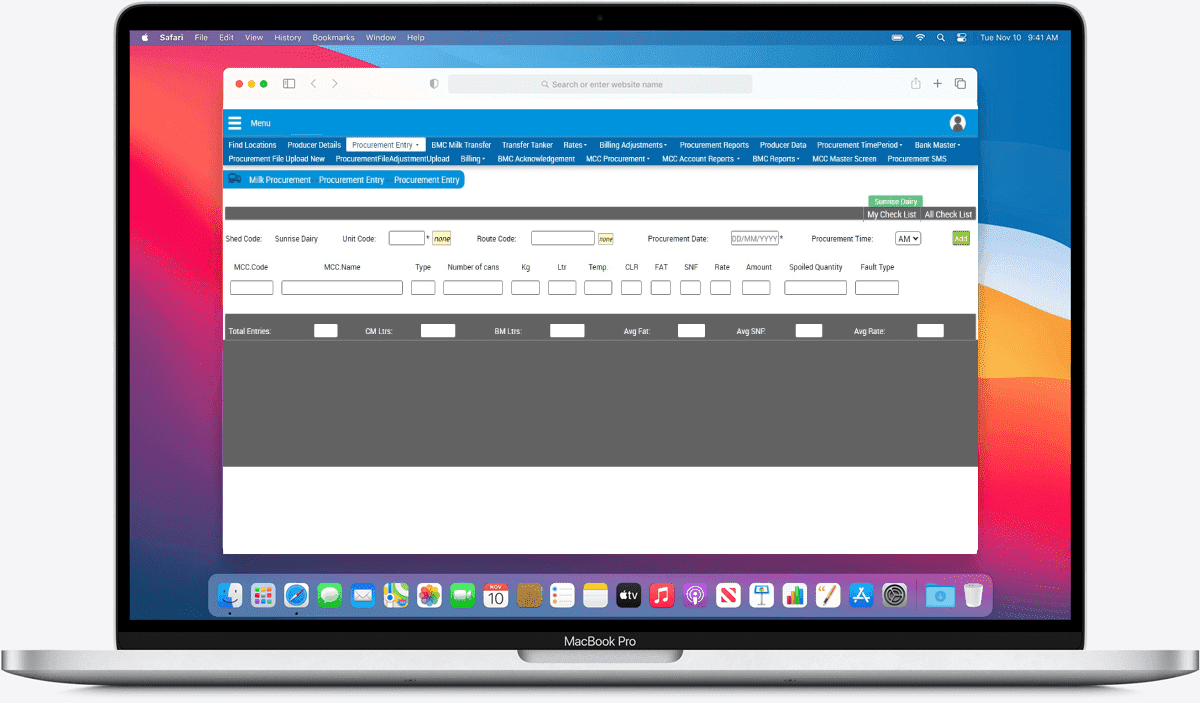

Milk collected from individual farmers at village collection centres needs to be shifted to Bulk Milk Collection Units (BMCUs) to preserve in a temperature-controlled storage container. Majority of the times dairies upgrade existing collection centres located at logistically convenient locations to a BMCU. While BMCUs of different capacities exist, the most commonly seen BMCU capacities range from 2500 Ltrs to 10000 Ltrs. Besides their own collection from farmers nearby, as hub centres, BMCUs aggregate milk from various smaller milk collection centres. Manual processes and legacy systems are fraught with several challenges not only in managing large volumes of data but also in protecting the quantity, quality especially Fat and SNF contents of the milk aggregated from a number of collection centres.

Digitizing these rural level milk movements through a tamper proof mechanism is critical to protect the quality of milk for the downstream dairy value chain.