Optimize the Production Process

Production planning and control is critical for production operations. While milk and milk products are rich in nutrients processing plants need to ensure that necessary controls are in place considering the highly perishable nature. Once the milk has been procured from the animal, the agility with which it is moved to the consumer’s table matters. Insights into profitability and product mix that best matches consumer preferences are very critical for planning. With a robust ERP system in place, the dairy supply chain can be optimized with a profitable product mix, better production and logistics planning and efficient execution of plant operations.

Milk Billing

Milk Billing Animal Health

Animal Health Artificial Insemination

Artificial Insemination BMCU Management

BMCU Management Tanker Receipt

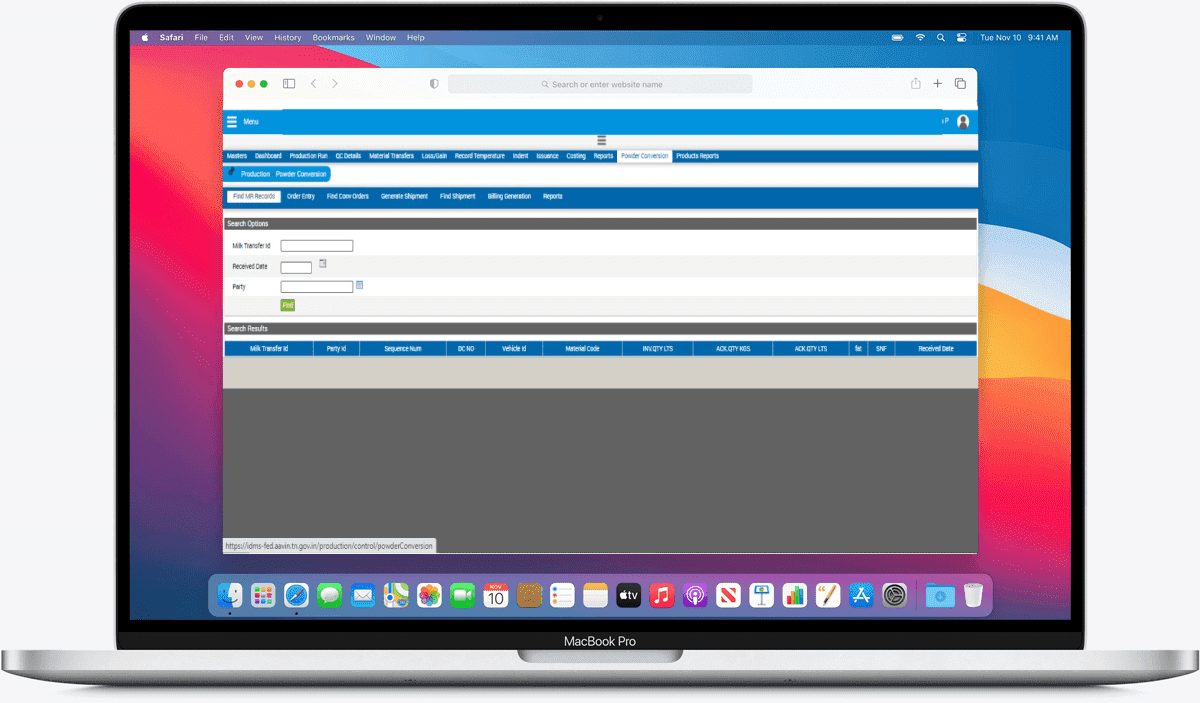

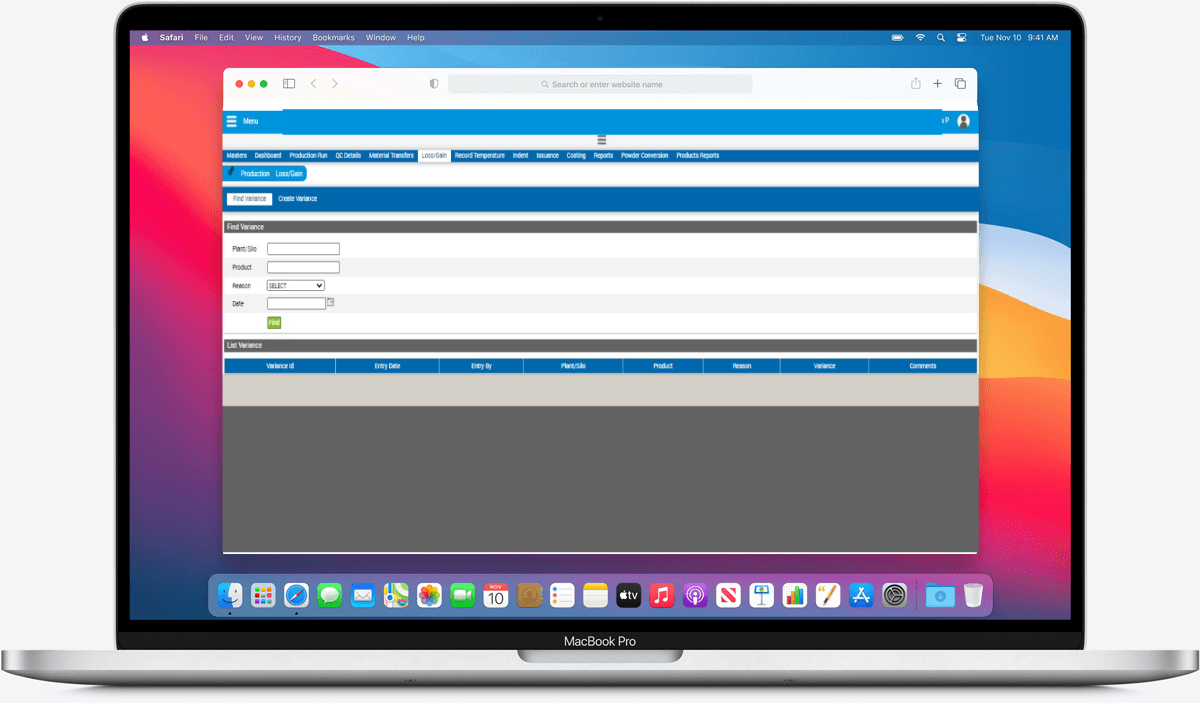

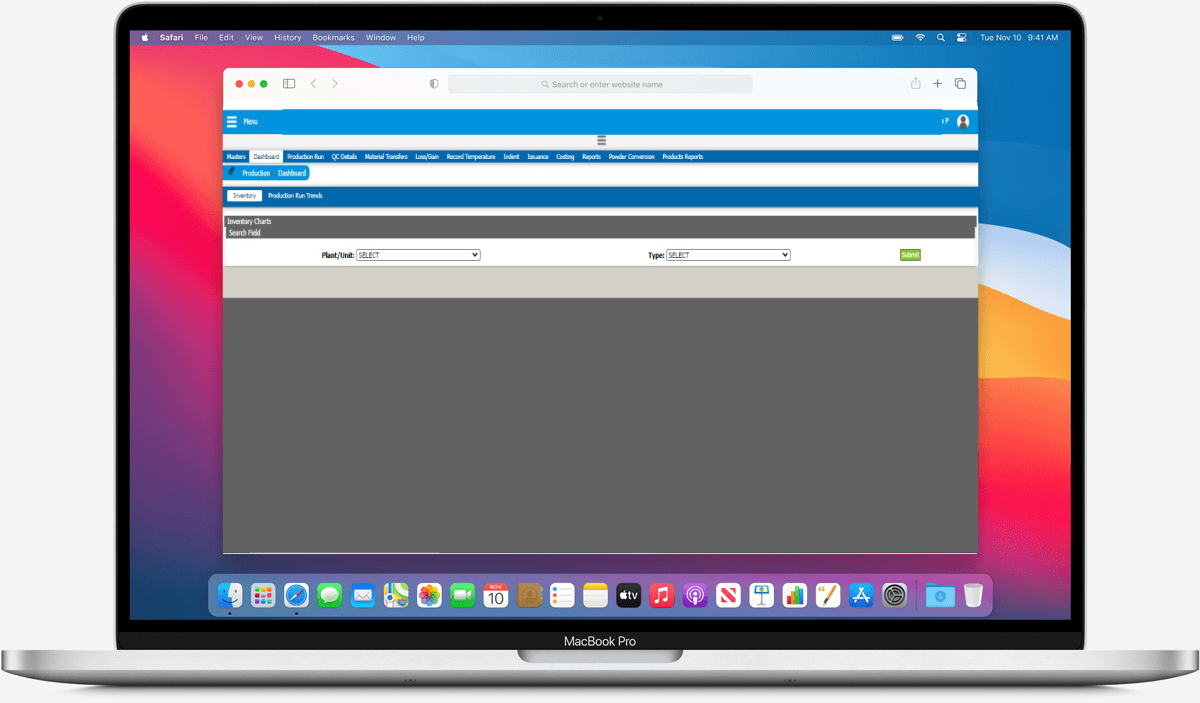

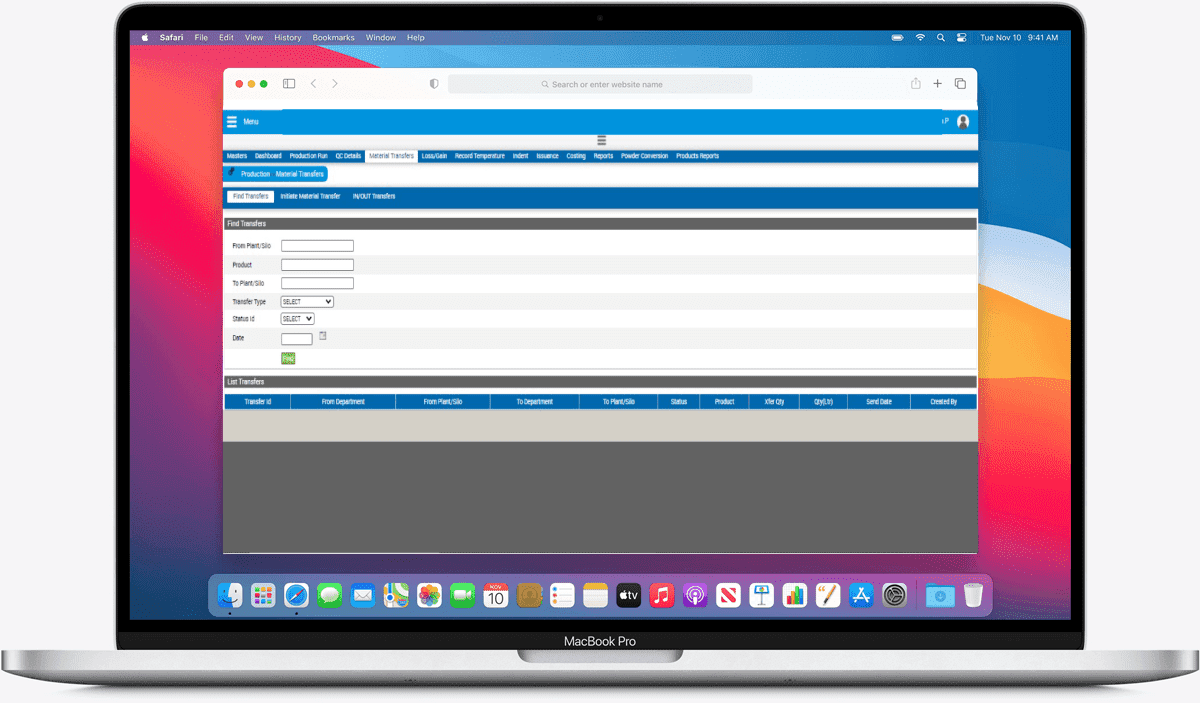

Tanker Receipt Production Module

Production Module Stores and Purchases

Stores and Purchases Dairy Engineering

Dairy Engineering Field Asset Management

Field Asset Management HR

HR Accounting

Accounting B2B Order Management

B2B Order Management D2C Order Management

D2C Order Management Sales Logistics

Sales Logistics Field Force Automation

Field Force Automation Sales Heat Maps

Sales Heat Maps Crates Management

Crates Management Distributor/Dealer Management System

Distributor/Dealer Management System