Eliminate errors and fraudulent activities

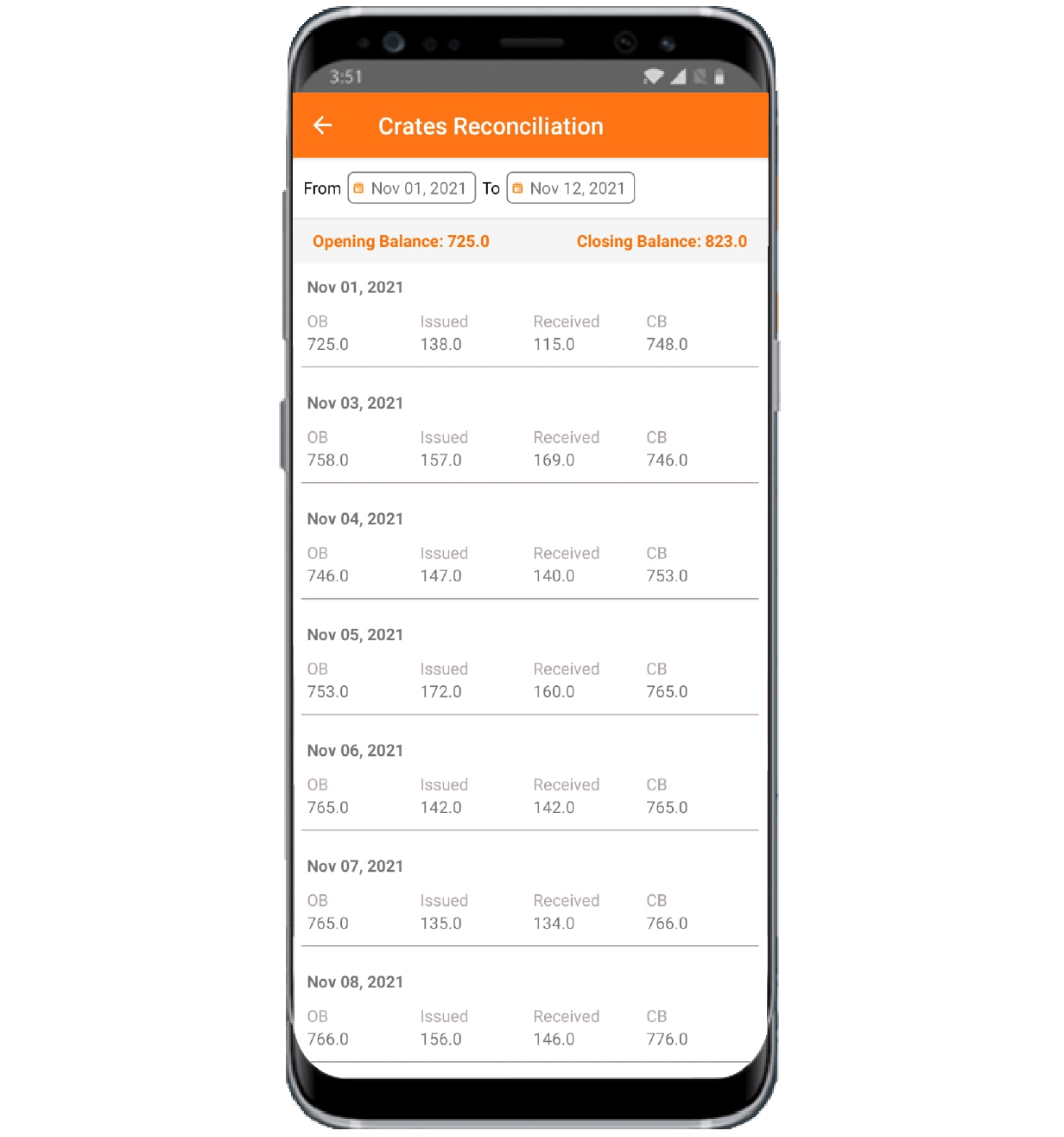

After the milk is produced, it is loaded onto trucks and vans to be dispatched to their respective retailers, distributors, or vendors. A specific number of milk packets are placed in every crate and the total number of crates is counted at the end to get an idea about the total products dispatched. This is a common method employed by a lot of dairies and distributors.

The problem with this method is that the transporters and van staff don’t always give the crates due importance. Instances of crates not returning to the plant or broken crates can be a cause of concern for plant managers. Lost or broken crates need to be replaced with new ones, which is an unnecessary cost burden and can be easily avoided with careful handling.